News

Site Editor

Site

https://kingspec.usa02.wondercdn.com/uploads/image/6307135a29359.png

The NAND cell stores electrons indefinitely on a capacitor in an off state. The load is then determined by the hardware on the NAND chip. The same technology is used in flash drives.

Site

https://kingspec.usa02.wondercdn.com/uploads/image/6307135a29359.png

The NAND cell stores electrons indefinitely on a capacitor in an off state. The load is then determined by the hardware on the NAND chip. The same technology is used in flash drives.

How Are SSDs Made?

Views: 12875

Author: Site Editor

Publish Time: 2022-06-21

Origin: Site

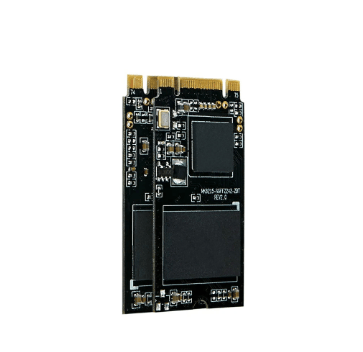

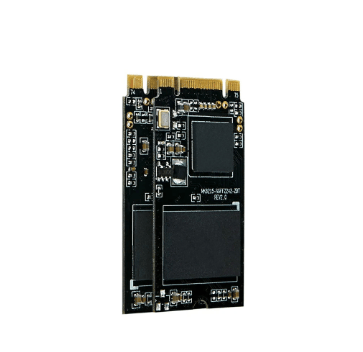

Media capacity is a vital variable that determines the performance and cost advantage of SSDs. Most solid-state drives are based on widely available NAND memory, which was developed in the late 1980s as an electron-based capacity carrier.

The NAND cell stores electrons indefinitely on a capacitor in an off state. The load is then determined by the hardware on the NAND chip. The same technology is used in flash drives.

The making of an SSD

An SSD is made of a few memory chips introduced on a circuit board. And these memory chips are made from silicon wafers, which are thin slices of semiconductors.

Because silicon wafers are susceptible to grounding, robots operate the wafers in more than 800 jobs, which takes more than a month to finish. As the wafers travel through the cycle, many layers of materials are added to the semiconductor wafer.

They combine solid materials, such as copper, and inorganic materials such as silicon dioxide. After each piece of material is applied, the wafer is covered with clean water, then, at that point, the bright light enters it by a glass sample and the design of the electrical equipment.

Where the light contacts the materials, they separate and break up. Where the materials are protected by the stencil, they stay in salvageable shape, which prints the hardware design on the wafer. Synthetic showers then wash away any remaining material.

After printing, each 30 cm wafer produces many flakes that need to be cut separately. After the flakes are separated, they are embedded in a protective plastic housing.

Large circuit boards are covered with tin plaster adhesive in the areas where memory blocks and various parts will be connected. A robot connects the pieces to the table, so at that point, the leaves collected go into a grid that matches the pieces at the table.

Other processes of the production

We will be diving into some basic processes in the production of an SSD.

Installation of the controller

The flash controller is a critical component that makes imperfect NAND flash reliable and reliable. The controller is a complex embedded system with independent processing and firmware to control every aspect of the SSD. It is designed to protect and control the underlying NAND flash memory.

Installation of the host interface

The host connection point is the exact connection between the hosting server and the SSD. SSDs affect current capabilities with communication guidelines, such as SATA (sequential ATA) and SAS (sequential join SCSI).

A new connection point for SSDs that are not used with PCIe (Peripheral Component Interconnect Express) HDDs. This is a similarly useful I / O port used on computers and servers.

Installation of the firmware

The firmware is installed in the controller and this enables the functionality of the SSD. The firmware could be seen as the operating software of the SSD.

The firmware can be quickly changed to add or remove key events, make up for missing the latest NAND package, or meet a hosting environment prerequisite. Some SSD manufacturers are considering updating the firmware, while many lock the firmware at build time.

Partner with us for your SSD

Sure, you are greatly equipped with how SSD is designed. It's the technology of the future.

We are the best producer of SSD, we design and produce top-notch quality SSDs. Attain efficient system uptime with our products. Kindly click here to order some.