News

Site Editor

Site

https://kingspec.usa02.wondercdn.com/uploads/image/6307135a29359.png

The use of industrial SSD for automation manufacturing provides the needed storage capacity to make the work easy. Sourcing a quality SSD for automation manufacturing from a reliable manufacturer is highly recommendable.

Site

https://kingspec.usa02.wondercdn.com/uploads/image/6307135a29359.png

The use of industrial SSD for automation manufacturing provides the needed storage capacity to make the work easy. Sourcing a quality SSD for automation manufacturing from a reliable manufacturer is highly recommendable.

An Overview of SSD for Automation Manufacturing

Views: 6477

Author: Site Editor

Publish Time: 2022-01-17

Origin: Site

With the need for greater output at reduced costs, manufacturers resort to automation manufacturing as the best approach to achieve this goal. Using this method provides high efficiency and upscaling of production in any company.

What exactly is automation manufacturing? It is a manufacturing technique that uses computerized control systems to carry out industrial production with automatic control as well as automatic adjustment devices. Industrial automatic control technology is evolving with networking, intelligence, and integration.

The use of industrial SSD for automation manufacturing provides the needed storage capacity to make the work easy. Sourcing a quality SSD for automation manufacturing from a reliable manufacturer is highly recommendable.

Some manufacturers do not know how to use automation to increase their production. However, the benefits of using it are enormous when you know the right type of automation manufacturing for your company.

Types of Automation Manufacturing

There are three major types of automation manufacturing. They are:

· Fixed automation

· Programmable automation

· Flexible automation

1. The Fixed Automaton

Fixed automation manufacturing is a method of automated manufacturing that has a specific task to carry out. It is also known as hard automation. The programming of the work is within the machine. It is used for large volume production.

The stages of processes and the speed are set by the production line or the equipment. An example of this type of automation manufacturing is the production of vehicle parts. Most times, there is no chance for changeovers during production.

2. Programmable Automation

In this method of manufacturing, different units are associated with batch production. It has the capacity to produce different types of products or parts. With this, you can handle low volume production conveniently.

However, there is a need for downtime before the performance of changeovers. The lead times and batch sizes are periods that the downtime is taken into consideration. The process is relatively expensive.

3. Flexible Automation

Flexible automation is a type of manufacturing method that can carry out changeovers automatically. There may be some limitations to equipment that run similar tools parts as well as more devices to cause automated changeovers.

Flexible automation is mostly connected to systems that rise value by offering remote control or monitoring. There is offline development of programs on the computer. A designer can run a new program, upload a new program, or work on the existing one from any part of the world.

Advantages of Using Automation Manufacturing

The trend of using automation for manufacturing is rising due to its positive impacts on every sector. The benefits are enormous and ranges from increased production, greater efficiency, production consistency, reduction in production costs, to ease of integrating sensors.

Storage Capacity Of Automation Manufacturing

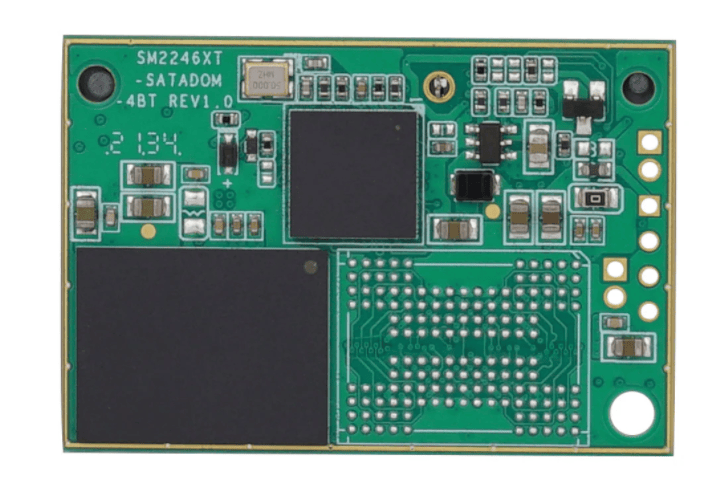

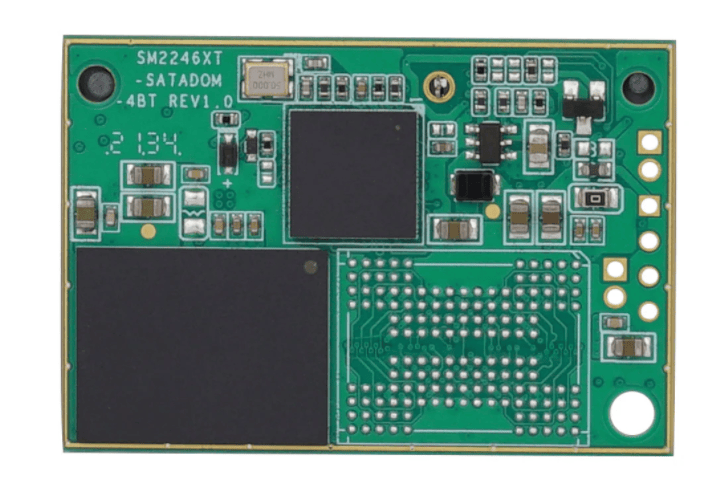

Storage is very essential in automation manufacturing. The capacity should be big enough to store data safely with high speed. The use of SSD for automation manufacturing makes the whole process easy and fast.

There are different SSDs for automated manufacturing. However, it is essential to purchase a quality SSD for automation manufacturing from a reliable and reputable manufacturer. Kindly click here to contact us for a quality product for your company.